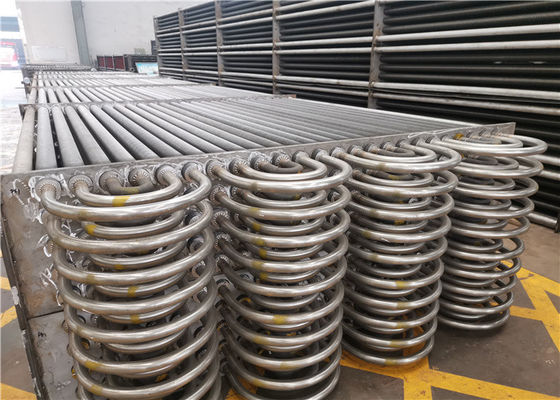

Alloy Steel HF Welding Spiral Type Boiler Fin Tube For Power Plants Heater Parts

Boiler fin Tube Introduction

Robust construction of finned tube that can withstand contrarious operating conditions over a long period.

Maximum transmission quality

High condensation rate

Wide application and temperature spectrum (range)

Very good value for money

Ideal for gas-liquid or gas-vapor heat transfer

Available as stainless steel finned tube heat exchanger

Highest reliability of operation through extensive quality inspection

Many years of experience in various fields of application

Spiral finned tube has been widely used in the heat recovery of coal economizer, air preheater and waste heat boiler, as well as heat exchange equipment in chemical industry and pressure vessel. Our products can be modified according to our customers' needs and the situation.we design and manufacture safe,reliable and efficient spiral fin tubes.it has also completed stand-alone product quality assurance systems.Production of spiral fin tubes are with high heat transfer efficiency, they have flue gas resistance and are designed for a small space.

Product Description

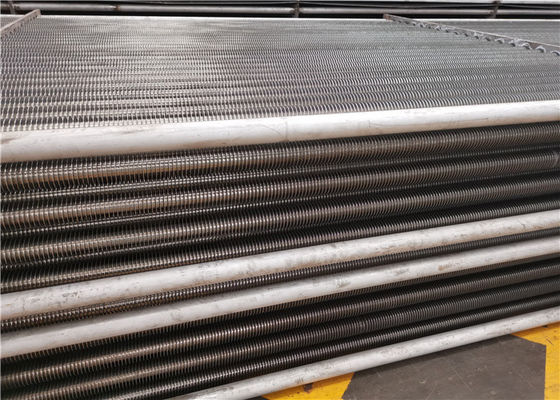

1.Finned Tube Heat Exchangers consist of a shell and finned tubes assembly.

2.Fins are used to increase the effective surface area of heat exchanger tubing.

3.Finned tubes are used when the heat transfer coefficient on the outside of the tubes is appreciably lower than that on the inside;as in heat transfer from a liquid to a gas,vapor to a gas ,such as steam to air heat exchanger, thermic fluid to air heat exchanger, when an extended surface is needed on only one fluid side or when the operating pressure needs to be contained on one fluid side.

Fin tube heat transfer area is 8 times than the light tube, high efficiency heat exchange, more advanced than the other heat exchange products.

Application: Boiler Economizer, Heat Exchange, Power Plant Waste Heat Boiler,Petrochemical Engineering.

Technical parameter

| Medium |

air, flue gas, thermal oil, water, brine, refrigerant, etc. |

| Temperature |

standard heat exchanger to 560 ° C by special materials can be higher |

| Pipe materials |

carbon steel, stainless steel, alloy or special materials |

| Ribs materials |

carbon steel, stainless steel, non-ferrous metal, alloy or special materials |

| Thermal insulation &Surface treatment |

according to customers specification

|

Features

1. The equipment body can be designed into many modules to ensure the long term and stable running;

2. Compact structure which can enlarge the heat exchanging area in order to add the heat transfer area and less leakage

3. Improve the heat transfer efficiency

4. Structure arrangement: In line or staggered arrangement

Details

1.Our products can be modified according to our customers' needs and the situation.

2.we design and manufacture safe,reliable and efficient H-fin tubes.HD BOILER has also completed stand-alone product quality assurance systems.

3.Production of H-fin tubes are with high heat transfer efficiency, they have flue gas resistance and are designed for a small space.

Quality Control

| 1 |

Impact test and Strength calculation report with applied materials information. |

| 2 |

100%NDT(non-destructive inspection) report of steel plate, tube and electrode. |

| 3 |

X-ray, γ-ray and liquid penetrant test inspection report (welding seam): to ensure the quality of the entire boiler. |

| 4 |

Hydraulic test report: ensure the standard working pressure and safety. |

Structure

Our products can be modified according to our customers' needs and the situation.we design and manufacture safe,reliable and efficient H-fin tubes.HD BOILER has also completed stand-alone product quality assurance systems.Production of H-fin tubes are with high heat transfer efficiency, they have flue gas resistance and are designed for a small space.

Company Introduction

For over 30years, Hua Dong Boiler has been consistently innovating and improving our boiler superheaters and reheaters.The improvements in bending,welding and design ensure our products meet both Euorpean and American standards, ensuring a relabile performance..

1, FACTORY DIRECT PRICE, PRICE NIE

2, 14 YEARS MANUFACTURE EXPERIENCE,NICE QUALITY GURANTEE

3, NATIONAL ENGINEER LEADING THE ENGINEER,STRONG DESIGN TECHNICAL TEAM

4, WE PROMISE 18 MONTHS QUALITY GURANTEE

5, SMALL ORDER IS ACCEPTED

6, SAMPLE IS AVAILABLE FOR YOU

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!