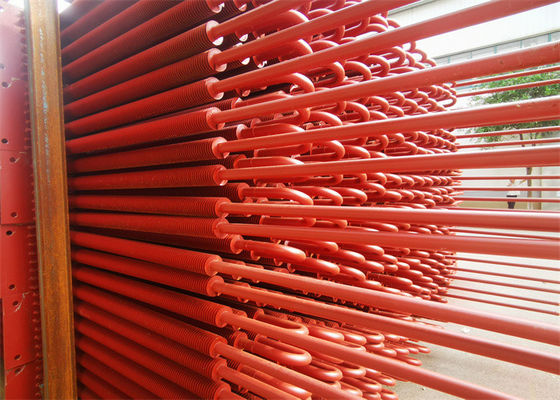

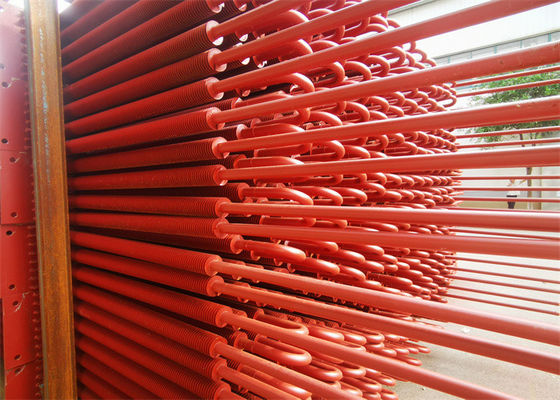

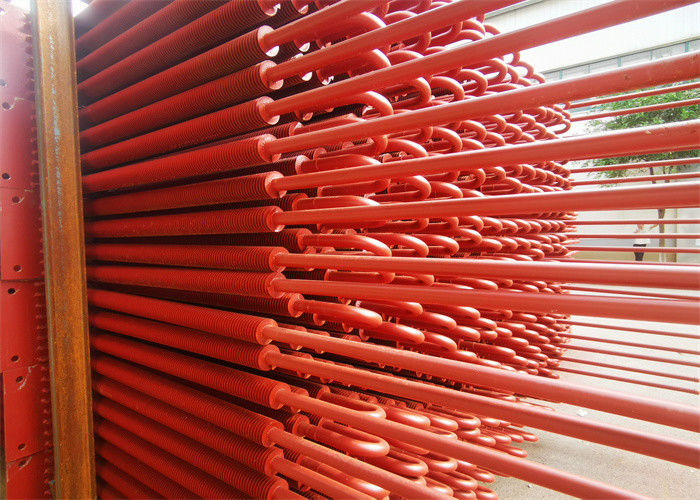

SA179/192 High Frequency Boiler Fin Tube 1.5mm Thickness Sprial Finned Tube

Product Description(Fin Tube)

In order to improve the heat exchange efficiency and extend surface heat transfer, spiral type finned tubes have been widely used in boilers and waste heat recovery in recent years. Spiral type finned tubes are derived largely from rectangle finned tubes. Because of their unique groove structure on the fin surface, spiral type finned tubes have excellent anti-wear and anti-fouling performance.

Spiral type finned tube heat exchanger elements maintain a high capacity for heat transfer, possess superior self-cleaning properties and retain the ability to effect flue gas waste heat recovery in boiler renovations. Convective heat transfer coefficient is proportional to fin pitch, but inversely proportional to fin height and fin width. Integrated heat transfer capacity is related to fin efficiency, convective heat transfer coefficient and finned ratio. Pressure drop increases with the increase of fin height and fin width.

Technical Parameters

| Item |

Base Tube O.D

(mm) |

Base Tube Thickness (mm) |

Fin Height (mm) |

Fin thickness(mm) |

Fin Pitch(mm) |

| Range |

25.4 mm ~1600mm |

2.5 mm ~40 mm |

0.5 mm ~20.0 mm |

0.5 mm ~3.0 mm |

5 mm ~ 25.4 mm |

| Material |

Carbon Steel,Alloy Steel,Stainless Steel |

| Length |

0<L≤ 12000 |

| Product |

Spiral Fin Tube |

| Base Pipe |

Welded or Seamless |

| Material |

carbon steel, alloy steel, stainless steel, non-ferrous alloys and nickel alloys. |

| Application |

H Heat Exchanger,H evaporator,H superheater,H air heater and etc. |

Principle

• Spiral fin tube is a kind of boiler parts, to have two steel circular symmetry to be welded on fluorescent tubes to form fins .

Structure

Our products can be modified according to our customers' needs and the situation.we design and manufacture safe,reliable and efficient spiral fin tubes.HD BOILER has also completed stand-alone product quality assurance systems.Production of H-fin tubes are with high heat transfer efficiency, they have flue gas resistance and are designed for a small space.

Quality Control

1. Impact test and Strength calculation report with applied materials information.

2. 100%NDT(non-destructive inspection) report of steel plate, tube and electrode

3. X-ray, γ-ray and liquid penetrant test inspection report (welding seam): to ensure the quality of the entire boiler

4. Hydraulic test report: ensure the standard working pressure and safety

Company Profile

Zhangjiagang Hua Dong Energy Technology Co., Ltd. is a high-tech enterprise specialized in producing all kinds of stainless, carbon and alloy steel tubes and pipes, steel plates which are widely used in the field of boiler&heat exchanger, energy, petrochemical, mining, food, paper, gas and fluid industry. And we have passed the attestations including ASME, TUV, Grade A, ISO9001, EN12952, EN10216, SO3834.

The company is the subsidiary of Zhangjiagang Hua Dong Boiler Co., Ltd, which is the most leading boiler and boiler parts manufacturer in China with a history of 35 years and annual turnover of 110 million U.S.A. dollars. Our products have been exported to over 30 countries like United States, Australia, Vietnam, Pakistan, Albania, Cambodia, India, Indonesia, South Korea, the Philippines, Turkey, Saudi Arab, Germany, Russia, Chile, Syria, Thailand, Bangladesh, France, Algeria, Mongolia and Singapore, Cuba, Iraq, Italy, Spain, Japan, Yugoslavia, Sri Lanka, the Czech republic, kyrgyzstan, Canada, Malaysia, the United Kingdom and so on.

Location:

Our company locates in Zhangjiagang city which is a port city, and is only 120km far away from Shanghai, 60km far away from Suzhou and 60km far away from Wuxi. The traffic is very convenient.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!