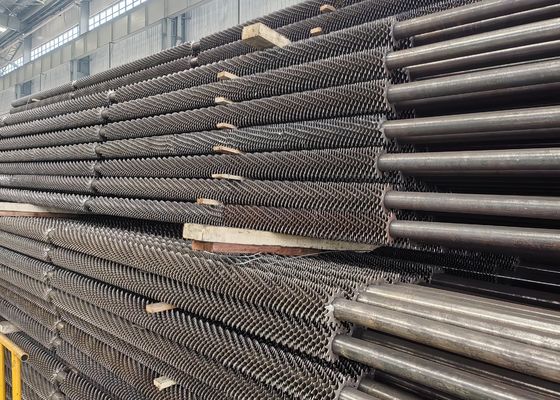

CE Standard Carbon Steel Boiler Parts Spiral Fin Tube Coil Boiler Tube For Economizer

Product Description

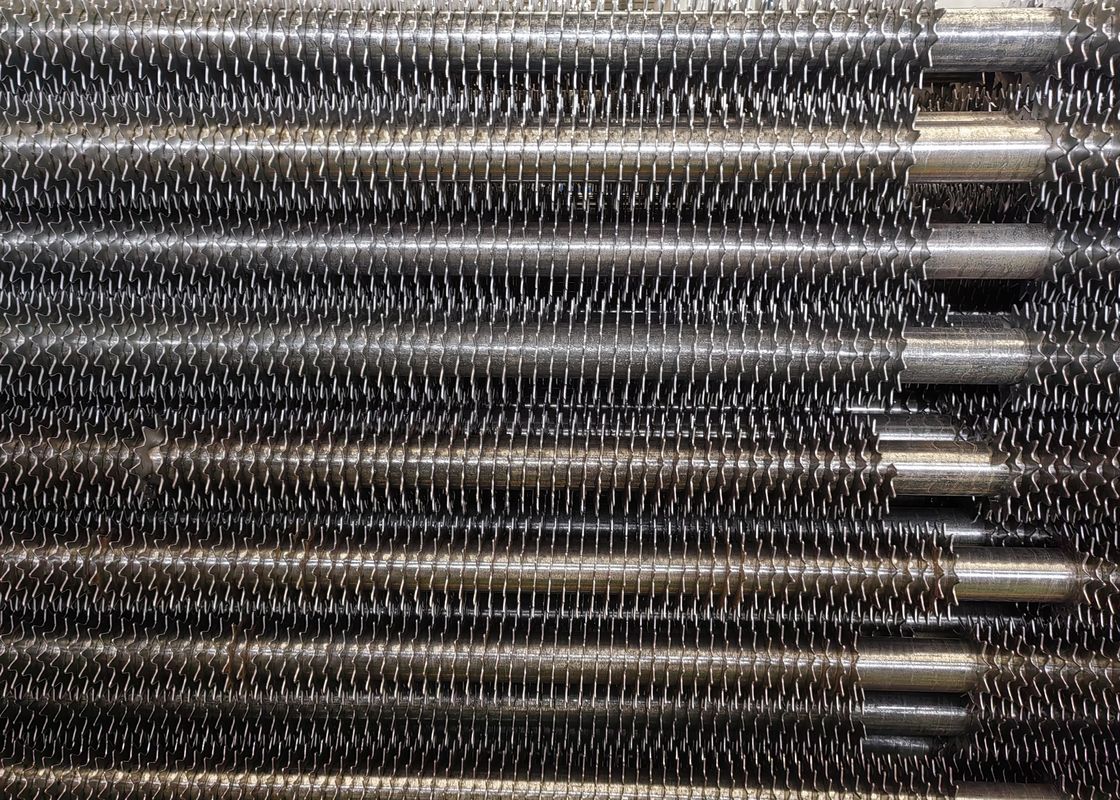

The finned tube is a tube with a heat sink or fins on the surface to improve heat transfer efficiency by increasing the heat dissipation area and improving the heat dissipation effect. Spiral finned tubes are made by wrapping a steel tube around a finned tube and then welding it or welding it at high frequency. This kind of finned tube has high heat transfer efficiency and anti-wear performance, but the manufacturing process is more complex and the cost is higher. The high-frequency welded finned tube is made by welding steel strip or aluminum strip on the surface of the steel pipe by high-frequency welding technology. This kind of finned tube has the characteristics of high heat transfer efficiency, long service life and moderate cost, and is widely used in various industrial fields.

Specifications

| Base Tube Material |

Stainless Steel, Carbon Steel, Alloy Steel, Copper Alloy,Aluminum ,SA179 |

| Fin Material |

Aluminum, Copper Alloy, Stainless Steel, Carbon Steel |

| Standard |

ASME SA213/ASTM; ASME EA 106, ASME SA178, ASTM B1111 |

| Fin depth |

0.5-3mm |

| Base pipe O.D |

12.7-18mm |

| Fins per inch |

8-20Nos (as customer's request) |

| Test Requirement |

Physical Property Test, Chemical Composition Analysis, Non-Destructive Test, Other Inspection and Test as customer's requirement. |

| Application |

Air Cooler, Charge Air Chiller, Condenser, Evaporator, Fluid Cooler, Gas Cooler, Oil Cooler, Radiator, Refrigeration, Steam to Air Heat Exchange, super heater etc. |

Features

- Boiler Fin Tube: Round, Square, Rectangle, Oval, Finned, Etc.

- Surface Treatment: Pickling, Sand Blasting, Galvanizing, Etc.

- Fin Pitch: Customized

- Package: Wooden Cases, Pallet, Etc.

- Application: Boiler, Heat Exchanger, Condenser, Etc.

- Heat Exchanger Fin Tube: Carbon Steel Fin Tube, Stainless Steel Fin Tube.

Advantages

1.The effective space increases the heat exchange area, improving the heat transfer effect.

2. Reduce the occupied space of the heat transfer surface and reduce its volume, especially suitable for quick-installation boilers.

3. Reduce the cost of equipment and improve the safety of equipment.

4. Lower operating costs due to the reduction of pressure drop on the water side.

5. The stiffness of the finned tube is increased, improving the seismic resistance of the tube.

Packing and Shipping

The boiler fin tubes are packaged in wooden crates or cartons, with each tube wrapped with an individual cardboard sleeve. The crates are then placed on a pallet and covered with a waterproof tarp to ensure the safety of the tubes during shipping.

The shipping method will depend on the size and quantity of the order. For smaller orders, the boiler fin tubes are shipped via small package carriers such as UPS or FedEx. For larger orders, the tubes are shipped via freight carriers such as R&L Carriers or Estes Express.

About us

Zhangjiagang Hua Dong Energy Technology Co., Ltd. is a high-tech enterprise specialized in producing all kinds of stainless, carbon and alloy steel tubes and pipes, steel plates which are widely used in the field of boiler&heat exchanger, energy, petrochemical, mining, food, paper, gas and fluid industry. And we have passed the attestations including ASME, TUV, Grade A, ISO9001, EN12952, EN10216, SO3834.

The company is the subsidiary of Zhangjiagang Hua Dong Boiler Co., Ltd, which is the most leading boiler and boiler parts manufacturer in China with a history of 35 years and annual turnover of 110 million U.S.A. dollars. Our products have been exported to over 30 countries like United States, Australia, Vietnam, Pakistan, Albania, Cambodia, India, Indonesia, South Korea, the Philippines, Turkey, Saudi Arab, Germany, Russia, Chile, Syria, Thailand, Bangladesh, France, Algeria, Mongolia and Singapore, Cuba, Iraq, Italy, Spain, Japan, Yugoslavia, Sri Lanka, the Czech republic, kyrgyzstan, Canada, Malaysia, the United Kingdom and so on.

FAQ

Q: What is Boiler Fin Tube?

A: Boiler Fin Tube is a kind of heat exchanger that is widely used in industrial boilers, HVAC systems, and other heat transfer equipment.

Q: What brand is HD Boiler Fin Tube?

A: HD Boiler is a Brand Name of Boiler Fin Tube.

Q: Where is HD Boiler Fin Tube made?

A: HD Boiler Fin Tube is made in China.

Q: What certifications does HD Boiler Fin Tube have?

A: HD Boiler Fin Tube has ASME, ISO9001:2015, ISOEN3834 certifications.

Q: What is the minimum order quantity of HD Boiler Fin Tube?

A: The minimum order quantity of HD Boiler Fin Tube is 3 TONS.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!