Product Description:

Our Boiler Fin Tube is designed with a fin thickness of 0.02 inches, providing a sturdy and robust structure that can withstand high-pressure environments. The high-pressure capability of our product ensures that it can handle the demands of any industrial process.

With a weight range of 5~50 ton, our Boiler Fin Tube is suitable for a wide range of applications. Whether you're looking to improve the efficiency of your power plant or need a reliable solution for your chemical processing facility, our product is the perfect choice for you.

The fin height of our Boiler Fin Tube is 2 inches, making it ideal for use in applications where space is limited. Despite its compact size, our product provides excellent heat transfer and can help improve the efficiency of your system.

Our Boiler Fin Tube is manufactured using high-frequency welding, which ensures a strong and reliable bond between the fin and the tube. This welding technique is known for its ability to produce high-quality joints that are resistant to corrosion and other types of damage.

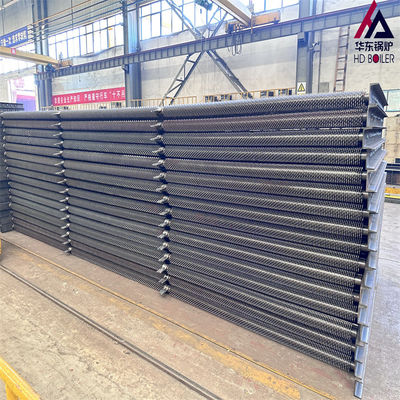

Our product is also known as a Boiler Economizer Tube or an H fin tube, which refers to the shape of the fin. The H-shaped fin design provides an increased surface area for heat transfer, making our product a highly efficient choice for any industrial process.

Overall, our Boiler Fin Tube is a top-quality product that is designed to meet the demands of high-pressure boiler systems. Its sturdy construction, efficient design, and reliable performance make it an ideal choice for a wide range of industrial applications.

Features:

- Product Name: Boiler Fin Tube

- Tube Diameter: 1 Inch

- Weight: 5~50ton

- Welding: High Frequency Welding

- Bare Tube: Cold Finished

- Fin Height: 2 Inches

- Used for heat exchange

- Also known as Boiler Economizer Tube

- Made of Carbon Steel Fin Tube

Technical Parameters:

| Product Name |

Boiler Fin Tube |

| Tube Type |

Seamless |

| Tube Diameter |

1 Inch |

| Bare Tube |

Cold Finished |

| Fin Type |

Extruded |

| Fin Height |

2 Inches |

| Fin Thickness |

0.02 Inches |

| Welding |

High Frequency Welding |

| Packing |

Seaworthy Packing Of Fin Tube |

| Port |

Shanghai |

| Origin |

Zhangjiagang, China |

Applications:

The fin tube has a fin height of 2 inches and a fin thickness of 0.02 inches. This makes it a highly efficient product that can withstand high temperatures and pressure. The fin tube is available in a range of weights, from 5 to 50 tons, making it suitable for use in various industrial applications.

The Boiler Fin Tube is commonly used in power plants, oil refineries, and chemical plants. It is used to recover heat from the flue gases that are generated during the combustion process. The sprial fin design of the tube increases the surface area, which in turn increases the heat transfer rate. This results in more efficient heat recovery and reduces the overall fuel consumption of the boiler.

The Boiler Fin Tube is an essential component of any economizer system. It is suitable for use in a wide range of operating conditions, including high temperatures and corrosive environments. This makes it a highly versatile product that can be used in a variety of industries.

Overall, the HD Technology's Boiler Fin Tube is a reliable and efficient product that is suitable for use in various industrial applications. Its sprial fin design, high-quality materials, and range of sizes make it an ideal choice for economizers in power plants, oil refineries, and chemical plants.

Support and Services:

Our Boiler Fin Tube product comes with comprehensive technical support and services to ensure that you get the most out of your purchase. Our team of experts is available to answer any questions you may have about installation, maintenance, and troubleshooting.

In addition to technical support, we also offer a range of services to help you maintain and optimize your Boiler Fin Tube. These include regular maintenance and cleaning, replacement parts, and upgrades to improve efficiency and performance.

Our commitment to customer satisfaction means that we are always here to help, whether you need assistance with a specific issue or simply want to learn more about how to get the most out of your Boiler Fin Tube.

Packing and Shipping:

Product Packaging:

The Boiler Fin Tube product will be carefully packed to ensure that it arrives in perfect condition. It will be wrapped in bubble wrap and placed inside a sturdy cardboard box. The box will be labeled with the product name, quantity, and any handling instructions if necessary.

Shipping:

The Boiler Fin Tube product will be shipped via standard ground shipping using a reputable carrier. The shipping time will depend on the destination, but customers can expect their product to arrive within 5-7 business days. Customers will receive a tracking number once their order has been shipped so that they can track their package.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!