Product Description:

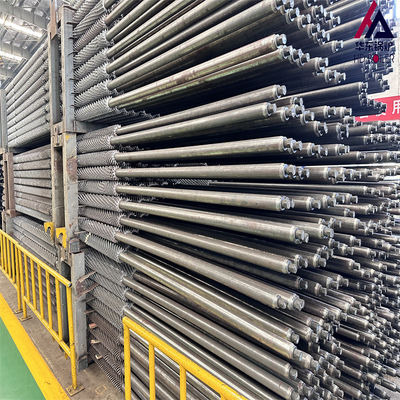

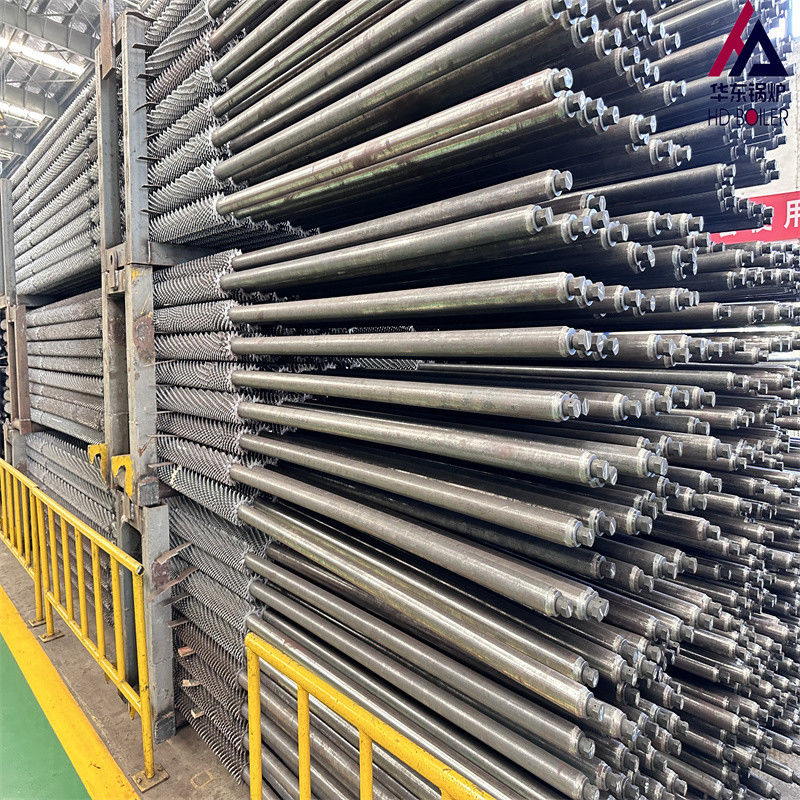

With a fin thickness of 0.02 inches, this H fin tube is optimized for maximum heat exchange efficiency, making it an ideal choice for use in boiler economizer tubes. The cold finished bare tube provides a secure and stable base for the finning, ensuring a tight and secure fit that maximizes thermal conductivity.

Each fin tube is carefully packed using seaworthy packing, ensuring safe and secure transport to your site. Our wooden box transport package is designed to protect the fin tube from damage during transit, giving you peace of mind and confidence in the quality of the product you receive.

This finned tube is designed for use in high-pressure systems, making it the perfect choice for use in modern boiler systems. The finning provides increased surface area, allowing for more efficient heat transfer and improved overall performance. This makes it ideal for use in applications where high pressure, high temperature, and high flow rates are present.

Overall, our Boiler Fin Tube product is a high-quality, reliable, and efficient choice for use in a wide range of industrial and commercial applications. Whether you're looking to improve your boiler system's performance, or simply looking for a durable and long-lasting finned tube, this product is sure to meet and exceed your expectations.

Features:

- Product Name: Boiler Fin Tube

- Port: Shanghai

- Fin Height: 2 Inches

- Tube Type: Seamless

- Fin Shape: Square Or Rectangular

- Transport Package: Wooden Box

- Features:

- Serrated Fin Tube

- Alloy Steel Finned Tube

Technical Parameters:

| Fin Height |

2 Inches |

| Port |

Shanghai |

| Fin Type |

Extruded |

| Weight |

5~50ton |

| Bare Tube |

Cold Finished |

| Fin Shape |

Square Or Rectangular |

| Packing |

Seaworthy Packing Of Fin Tube |

| Sales Location |

Middle East |

| Fin Thickness |

0.02 Inches |

| Welding |

High Frequency Welding |

Applications:

Boiler Fin Tube is a crucial component in heat exchangers and boilers. They are used in a variety of industries, including petroleum, chemical, power generation, and HVAC. Our product is designed to transfer heat effectively and efficiently, ensuring that the equipment operates optimally.

The high-frequency welding technology used in the production process ensures that our product is of high quality and durability. HD Technology's Boiler Fin Tube is also resilient to corrosion and can withstand extreme temperatures. This makes it ideal for use in harsh environments.

The product application occasions and scenarios for HD Technology's Boiler Fin Tube are extensive. It is ideal for use in industrial boilers, heat exchangers, power plants, and other equipment that requires efficient heat transfer. Our product is also suitable for use in petrochemical plants, where it can transfer heat between fluids without contamination.

HD Technology's Boiler Fin Tube is also perfect for use in HVAC systems. The product's ability to transfer heat effectively ensures that the system operates optimally, providing a comfortable indoor environment. The product's durability also makes it ideal for use in outdoor HVAC units.

Our product is transported in wooden boxes, ensuring that it arrives at the destination in perfect condition. The boxes also protect the product during storage and handling.

In conclusion, HD Technology's Boiler Fin Tube is a high-quality product that is ideal for use in various industries. Its ability to transfer heat efficiently makes it a valuable component in heat exchangers and boilers. Our product's durability and resilience to corrosion make it ideal for use in harsh environments. Contact us to learn more about our product and how it can benefit your business.

Support and Services:

Our Boiler Fin Tube product comes with a comprehensive technical support and services package to ensure that our customers have everything they need to maintain their equipment and keep it running at peak performance.

Our technical support team is available to answer any questions and provide guidance on installation, operation, and maintenance. We also offer training programs for customers who want to expand their knowledge and skillset.

In addition, we provide a range of services including equipment repair and refurbishment, replacement parts, and custom design and fabrication. Our goal is to help our customers get the most out of their Boiler Fin Tube product and minimize downtime.

For more information on our technical support and services, please contact our customer service team.

Packing and Shipping:

Product Packaging:

- The boiler fin tube will be securely packaged in a cardboard box.

- The box will be sealed with tape to ensure the product is not damaged during shipping.

Shipping:

- The product will be shipped via a reliable courier service.

- The shipping cost will be calculated based on the destination and weight of the package.

- The estimated delivery time will be provided to the customer upon checkout.

- A tracking number will be provided to the customer once the product has been shipped.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!