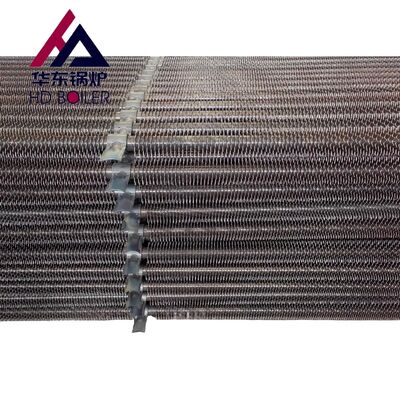

High-Frequency Welding Carbon Steel Boiler Spiral Fin Tube

The spiral fin tube consists of a base tube and spiral fins welded to its outer surface. The base tube is typically manufactured from steel, copper, or aluminum, with other metal materials available based on specific requirements. The spiral fins create an extended heat transfer surface that significantly enhances thermal efficiency.

Key Advantages

- High heat transfer efficiency: Extended surface area reduces thermal resistance and improves overall performance

- Compact structure: Increased heat transfer area allows for smaller, more efficient heat exchanger designs

- Wide application range: Suitable for various media including water, steam, and heat transfer oil across multiple industries

- Excellent mechanical properties: Strong tensile, compressive, and fatigue resistance for long-term reliability

Product Specifications

- Boiler Fin Tube Types: Round, Square, Rectangle, Oval, Finned, etc.

- Surface Treatment: Pickling, Sand Blasting, Galvanizing, etc.

- Fin Pitch: Customized to requirements

- Packaging: Wooden Cases, Pallets, etc.

- Applications: Boiler, Heat Exchanger, Condenser, etc.

- Heat Exchanger Fin Tube Materials: Carbon Steel, Stainless Steel

Technical Parameters

| Parameter |

Description |

| Fin Height |

Customized |

| Thickness |

Customized |

| Package |

Wooden Cases, Pallet, etc. |

| Length |

Customized |

| Fin Pitch |

Customized |

| Application |

Boiler, Heat Exchanger, Condenser, Boiler Fin Tube Heat Exchanger, Fin And Tube Heat Exchanger, etc. |

| Material |

Carbon Steel, Alloy Steel, Stainless Steel, Copper, Aluminum, etc. |

| Size |

Customized |

| Shape |

Round, Square, Rectangle, Oval, Finned, etc. |

| Standard |

ASME, ASTM, EN, JIS, DIN, etc. |

Applications

HD Boiler Fin Tube is a premium carbon steel fin tube widely used in boilers, heat exchangers, condensers, and fin and tube heat exchanger applications. Manufactured in compliance with ASME, ISO9001:2015, and ISOEN3834 standards, these tubes are available in customized sizes and thicknesses to meet specific customer requirements. Packaging options include iron frame packing, wooden cases, and pallets to ensure safe transportation.

Packaging and Shipping

Boiler fin tubes are securely packaged in wooden crates or cartons, with each tube individually wrapped in cardboard sleeves. Crates are placed on pallets and covered with waterproof tarps to ensure protection during transit. Shipping methods vary based on order size: smaller orders ship via carriers like UPS or FedEx, while larger orders utilize freight carriers including R&L Carriers or Estes Express.

Manufacturing Excellence

Hua Dong Boiler Co., Ltd. is a high-tech enterprise established in 1985 with two manufacturing bases covering 400,000 m². With fixed assets of USD 110,000,000 and 1,100 employees including 150 technicians and 600 certified welders, the company holds Grade A boiler and Grade A1&A2 pressure vessel manufacturing licenses. Additional certifications include ASME "S", "U", and "NB" stamps, along with ISO9001, SO3834, and EN12952 Quality Management System approvals.

Frequently Asked Questions

What is Boiler Fin Tube?

Boiler Fin Tube is a heat exchanger component widely used in industrial boilers, HVAC systems, and other heat transfer equipment.

What brand is HD Boiler Fin Tube?

HD Boiler is the brand name for our boiler fin tube products.

Where is HD Boiler Fin Tube made?

HD Boiler Fin Tube is manufactured in China.

What certifications does HD Boiler Fin Tube have?

Our products hold ASME, ISO9001:2015, and ISOEN3834 certifications.

What is the minimum order quantity of HD Boiler Fin Tube?

The minimum order quantity is 3 tons.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!