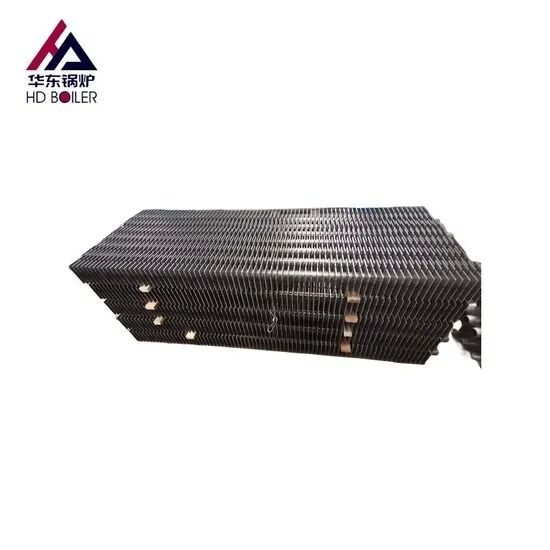

H Finned Boiler Fin Tube Carbon Alloy Stainless Steel Heat Exchanger

Finned tubes are engineered to significantly enhance heat exchanging efficiency by extending the surface area through the addition of fins onto tubes. This manufacturing process substantially improves heat transfer efficiency in heating applications.

Finned Tube Types

- Welded finned tubes

- Extruded finned tubes

- Welded helical solid finned tubes

- Welded serrated finned tubes

- Welded helical serrated finned tubes

Product Specifications

Dimensional Parameters

| Item |

Base Tube O.D (mm) |

Base Tube Thickness (mm) |

Fin Height (mm) |

Fin Thickness (mm) |

Fin Pitch (mm) |

| Range |

25.4 mm - 1600 mm |

2.5 mm - 40 mm |

0.5 mm - 20.0 mm |

0.5 mm - 3.0 mm |

5 mm - 25.4 mm |

Material & Construction

Materials: Carbon Steel, Alloy Steel, Stainless Steel

Length: 0 < L ≤ 12000 mm

Product Details

| Product |

Fin Tube |

| Base Pipe |

Welded or Seamless |

| Material |

Carbon steel, alloy steel, stainless steel, non-ferrous alloys and nickel alloys |

| Application |

Economizer, Evaporator, Superheater, Air heater and etc. |

Packaging & Shipping

• For special cargos (overlength, overwidth, overheight, overweight), we use frame boxes for easy handling

• For regular goods, we prefer ordinary containers

• All goods are properly reinforced after loading

Company Profile

Zhangjiagang Hua Dong Boiler Co., Ltd., founded in 1985, specializes in manufacturing power station boilers, industrial boilers, HRSGs, waste incineration boilers, biomass boilers and related heating surface components. We provide integrated services from design and manufacturing to installation and maintenance.

Our Advantages

38 years of industry experience in research, development and manufacturing with sufficient production capacity.

Quality Control

- Impact test and Strength calculation report with applied materials information

- 100% NDT (non-destructive inspection) report of steel plate, tube and electrode

- X-ray, γ-ray and liquid penetrant test inspection report (welding seam)

- Hydraulic test report to ensure standard working pressure and safety

Complete quality assurance and control system certified according to International Quality Standards. We establish quality assurance systems in compliance with national regulations, standards and technical requirements, ensuring 100% process and product quality control.

Certifications

Global Sales

Frequently Asked Questions

Q1: How long is the warranty period?

We provide 18 months warranty for all spare parts (excluding fragile parts).

Q2: How can we guarantee quality?

1) All machines comply with ISO quality and CE system requirements

2) Each procedure is crafted by professional skilled labor with dedicated QC

3) All product information is tracked in our efficient management system

Q3: What can you buy from us?

CFB Boiler, HRSG Boiler, Boiler Economizer, Boiler Fin tube, Boiler Air preheater, Boiler superheater, Boiler membrane wall, Boiler manifold headers and other pressure spare parts.

Q4: What kind of service do you provide?

Before sales: Product information, market research forecasting, product customization, product processing, consultation services

After sales:

1. Technical training according to customer requirements

2. Replacement under warranty

3. Maintenance spare parts supply

4. Regular customer follow-up

5. Prompt response to complaints and consultations

Delivery Terms: FOB, CFR, CIF, EXW, FCA

Payment Currency: USD, CNY

Payment Type: T/T, L/C, MoneyGram, Western Union, Cash

Languages: English, Chinese

Q5: Are you a factory or trading company, where are you located?

We are a factory located just 130km (2 hours by car) from Shanghai Airport. We offer pickup service at Shanghai for your visit.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!